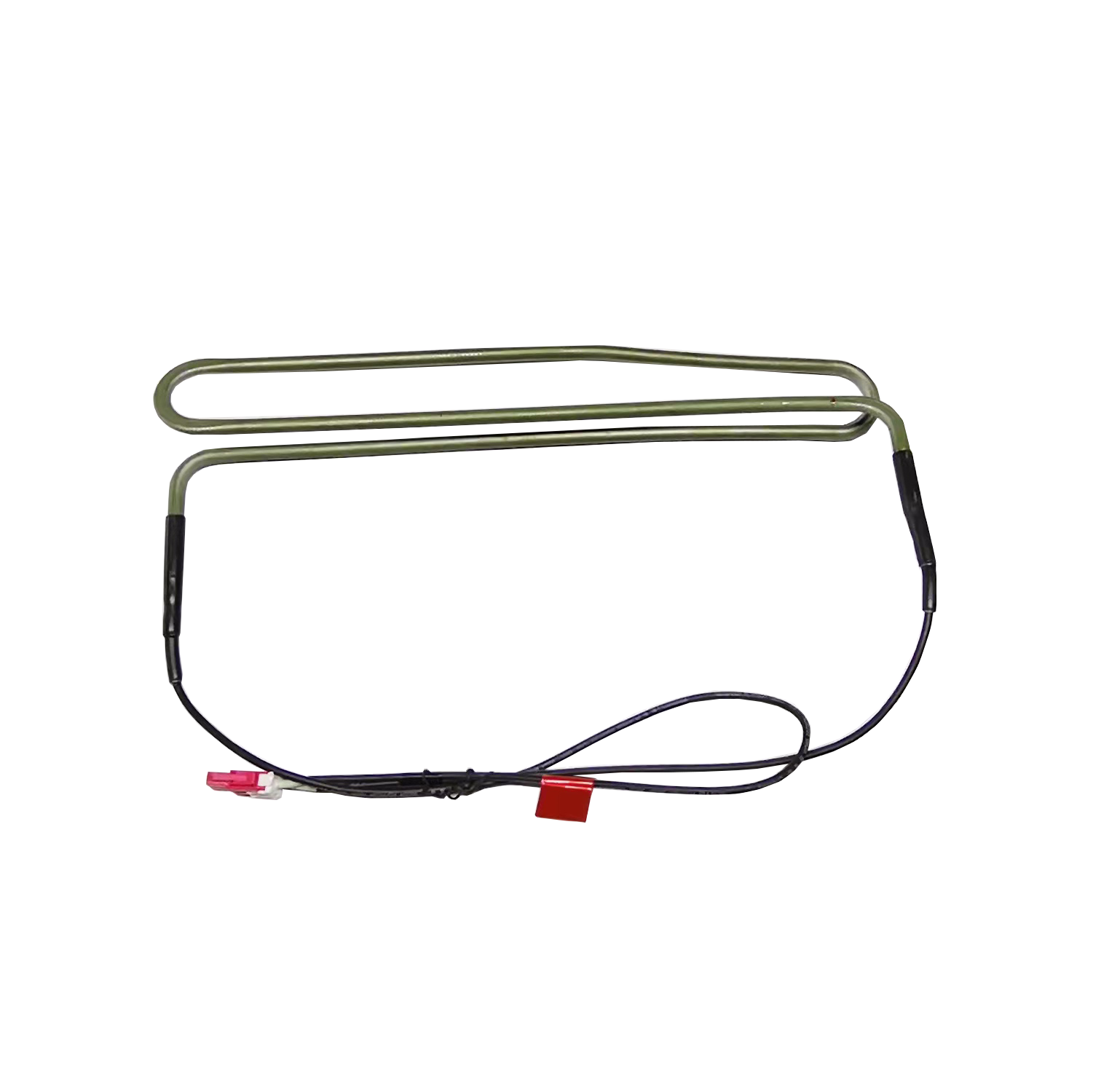

I-TUV Certified Tubular Defrost heater Genuine Defrost Heating Element Yasekhaya Izingxenye 1.DA0196201

Ipharamitha Yomkhiqizo

| Igama Lomkhiqizo | I-TUV Certified Tubular Defrost heater Genuine Defrost Heating Element Yasekhaya Izingxenye 1.DA0196201 |

| I-Humidity State Insulation Resistance | ≥200MΩ |

| Ngemuva kwe-Humid Heat Test Insulation Resistance | ≥30MΩ |

| Ukuvuza Kwesimo Somswakama Kwamanje | ≤0.1mA |

| Umthwalo ongaphezulu | ≤3.5W/cm2 |

| Izinga Lokushisa Lokusebenza | 150ºC(Ubukhulu obungu-300ºC) |

| Izinga lokushisa le-ambient | -60°C ~ +85°C |

| I-voltage engazweli emanzini | 2,000V/min (izinga lokushisa elivamile lamanzi) |

| Ukumelana ne-insulated emanzini | 750MOhm |

| Sebenzisa | Isici Sokushisa |

| Izinto eziyisisekelo | Insimbi |

| Isigaba sokuvikela | IP00 |

| Izimvume | UL/TUV/VDE/CQC |

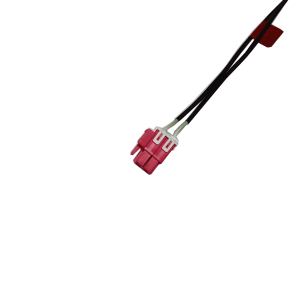

| Uhlobo lwetheminali | Ngokwezifiso |

| Ikhava/Ubakaki | Ngokwezifiso |

Izinhlelo zokusebenza

- Isiqandisi nezinto zokupholisa

- Compressors

- Amakhishi ochwepheshe

- HVAC

- Ukusetshenziswa kwangaphandle.

Ukwakheka Komkhiqizo

Isici sokushisa se-Stainless Steel Tube sisebenzisa ipayipi lensimbi njengesithwali sokushisa. Faka ingxenye ye-heater ku-Stainless Steel Tube ukuze wakhe izingxenye zomumo ezihlukene.

Izici

(1) Isilinda sensimbi engagqwali, ivolumu encane, ukusebenza okuncane, ukuhamba kalula, ukumelana nokugqwala okuqinile.

(2)Intambo yokumelana nezinga lokushisa eliphezulu ifakwa eshubhuni lensimbi engagqwali, futhi i-crystalline magnesium oxide powder ene-insulation enhle kanye ne-thermal conductivity igcwaliswa ngokuqinile engxenyeni engenalutho. Ukushisa kudluliselwa eshubhu lensimbi ngokusebenzisa umsebenzi wokushisa wentambo kagesi yokushisisa, ngaleyo ndlela kushise. Ukusabela okusheshayo okushisayo, ukunemba kokulawula izinga lokushisa eliphezulu, ukusebenza kahle okuphezulu kokushisa okubanzi.

(3)Isendlalelo sokufakwa okushisayo esijiyile sisetshenziswa phakathi komugqa wensimbi engagqwali kanye negobolondo lensimbi engagqwali, okunciphisa ukulahleka kwezinga lokushisa, okugcina izinga lokushisa futhi konga ugesi.

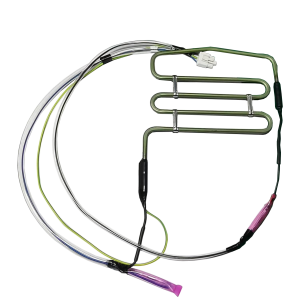

Defrost Component Izindawo

Eziqandisini eziningi ezingenasithwathwa, ikhoyili ye-evaporator (epholile) ingaphakathi kwegumbi lesiqandisi elimbozwe yiphaneli. Injini yefriji yesiqandisi ivamise ukuba sendaweni ejwayelekile efanayo.

I-heater ye-defrost ifakwa phezu noma ilukwe ngqo kukhoyili ye-evaporator efrijini. I-defrost termination switch ivamise ukugxunyekwa eceleni kwekhoyili ye-evaporator noma kwelinye lamashubhu axhumayo.

Isibali sikhathi se-defrost singaba ezindaweni ezihlukahlukene kuhlanganise ngemuva kwe-kickplate ngaphambili kwekhabhinethi, ngaphakathi kwegumbi lesiqandisi ngokunokwenzeka kuphaneli yokulawula kanye ne-thermostat noma kumamodeli amadala, ngemuva endaweni yemoto yi-compressor.

Umkhiqizo wethu usuphumelele isitifiketi se-CQC, UL, TUV nokunye, ufake isicelo samalungelo obunikazi ngokunqwabelana kwamaphrojekthi angaphezu kuka-32 futhi uthole iminyango yocwaningo lwesayensi ngaphezu kwezinga lesifundazwe nelongqongqoshe amaphrojekthi angaphezu kwe-10. Inkampani yethu iphinde yaphasisa uhlelo lwe-ISO9001 kanye ne-ISO14001 olunesitifiketi, kanye nohlelo lukazwelonke lwempahla yengqondo egunyaziwe.

Umkhiqizo wethu usuphumelele isitifiketi se-CQC, UL, TUV nokunye, ufake isicelo samalungelo obunikazi ngokunqwabelana kwamaphrojekthi angaphezu kuka-32 futhi uthole iminyango yocwaningo lwesayensi ngaphezu kwezinga lesifundazwe nelongqongqoshe amaphrojekthi angaphezu kwe-10. Inkampani yethu iphinde yaphasisa uhlelo lwe-ISO9001 kanye ne-ISO14001 olunesitifiketi, kanye nohlelo lukazwelonke lwempahla yengqondo egunyaziwe.

Ucwaningo lwethu nokuthuthukiswa kanye namandla okukhiqiza izilawuli zokushisa zemishini nezikagesi zikleliswe phambili embonini efanayo ezweni.